Snap Hooks

-

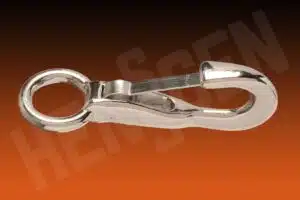

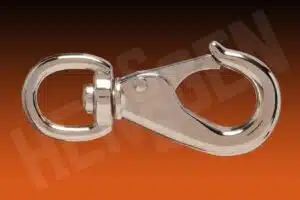

Harness Swivel Eye Bolt Snap 1″

$1.57 -

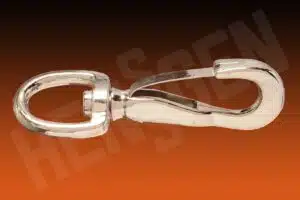

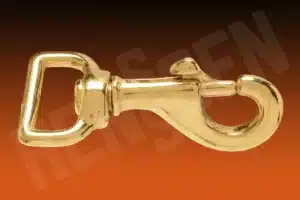

Harness Fixed Eye Bolt Snap 1″

$1.63 -

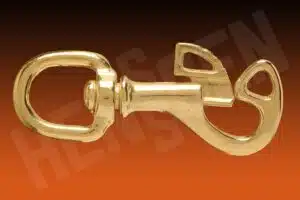

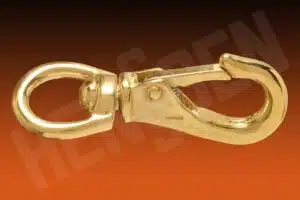

Deluxe Harness Swivel Snap 1″

$1.30 -

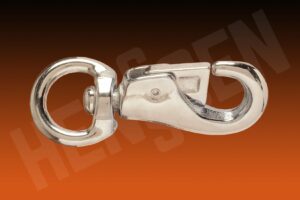

Fixed Round Eye Spring Snap 5/8″

$1.29 -

Swivel Eye Spring Snap 3/4″

$1.43 -

Fixed Eye Spring Snap 3/8″

$0.48 -

Harness Swivel Spring Snap 5/8″

$0.61 -

Swivel Eye Harness Snap 1″

$1.82 -

Panic Snap Fixed Eye 3/4″

$3.28 -

Key Ring Snap Hook

$1.43 -

Open Swivel Eye Spring Snap

$0.78 -

Swivel Eye Baby Bolt Snap

$0.64 -

Swivel Spring Snap 3/4″

$2.98 -

Swivel Spring Snap Heavy Duty 7/8″

$4.71 -

Open Eye Swivel Snap 1″

$5.50 -

Bull Snap Swivel Eye 1″

$7.58 -

Swivel Eye Quick Snap 3/4″

$3.73 -

Fixed Eye Spring Snap 3/8″

$2.50 -

162 Double End Bolt Snap

$6.21 -

Heavy Bull Snap Swivel Eye

$4.95 -

Extra Heavy Bull Snap Swivel Eye

$5.32 -

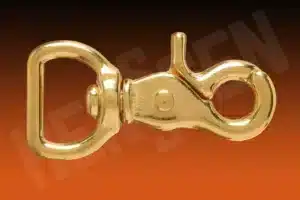

Bull Snap Fixed Eye 7/8″

$2.99 -

Bull Snap Swivel Harness Eye 1″

$3.51 -

Fixed Eye Snap 5/8″

$1.13 -

Panic Snap with Harness Eye 1″

$5.46 -

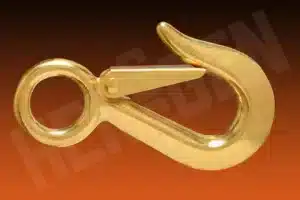

Drop Forged Steel Hook 5/8″

$2.93 -

Flat Wire Simplex Snap

$0.09 -

Bit Snap

$0.39 -

Breaching Snap

$0.49 -

Deluxe Swivel Eye Bolt Snap

$1.29 -

Fixed Round Eye Bolt Snap

$1.26 -

Double End Bolt Snap

$1.55 -

Swivel Round Eye

$0.99 -

Harness Fixed Eye Spring Snap

$1.17 -

Small Swivel Eye Bolt Snap Zinc Die Cast

$0.95 -

Swivel Eye Bolt Snap Zinc Die Cast

$1.25 -

Jumbo Swivel Eye Bolt Snap Zinc Die Cast

$1.59 -

Utility Snap Fixed Eye

$0.82 -

Swivel Eye Boat Snap

$1.43 -

Swivel Eye Spring Snap

$0.60 -

Harness Fixed Eye Spring Snap

$0.49 -

Swivel Eye Spring Snap

$0.56 -

Swivel Snap

$2.07 -

Panic Snap Swivel Eye

$2.99 -

Swivel Eye Trigger Snap

$1.17 -

Harness Swivel Eye Trigger Snap

$1.34 -

Large Swivel Eye Trigger Snap

$1.81 -

Swivel Eye Bolt Snap

$0.90 -

Swivel Eye Pulley

$1.20 -

Fixed Eye Pulley

$0.85 -

Fixed Eye Double Pulley

$1.03 -

Swivel Eye Double Pulley

$1.37 -

Harness Swivel Eye Bolt Snap

$3.67 -

Fixed Eye Harness Snap

$3.00 -

Fixed Eye Boat Snap

$2.08 -

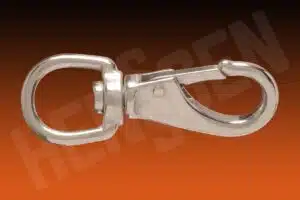

Swivel Eye Boat Snap

$3.84 -

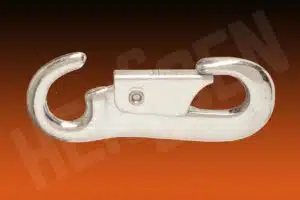

Swivel Quick Release Panic Snap

$7.49 -

Brass Hook Round Eye

$5.50 -

Trigger Snap

$2.26 -

Harness Eye Trigger Snap

$2.51 -

Swivel Round Eye

$3.20 -

Double End Bolt Snap

$3.71 -

Harness Swivel Eye Bolt Snap

$2.46 -

Swivel Eye Bolt Snap

$2.20 -

Open Eye Swivel Bolt Snap

$2.87 -

Open Eye Bolt Snap

$3.61 -

Swivel Eye Bolt Snap

$5.46 -

All Purpose Snap Stainless

$1.83 -

All Purpose Snap With Grommet Stainless

$1.83 -

Fixed Eye Boat Snap

$3.76 -

Swivel Eye Boat Snap

$6.03 -

Simplex Snap

$0.69 -

Bull Snap Swivel Eye 7/8″

$3.25 -

Double Snap

$1.64 -

Open Eye Snap

$1.48 -

Swivel Eye Bolt Snap

$2.00 -

Open Eye Bolt Snap

$2.00 -

Simplex Snap with Swivel

$0.55 -

Simplex Snap without Swivel

$0.29 -

All Purpose Snap

$0.65 -

All Purpose Snap with Grommet

$1.00 -

German Scissor Snap

$3.19 -

Swivel Quick Release Panic Snap 3/4″

$6.86

Snap Hooks