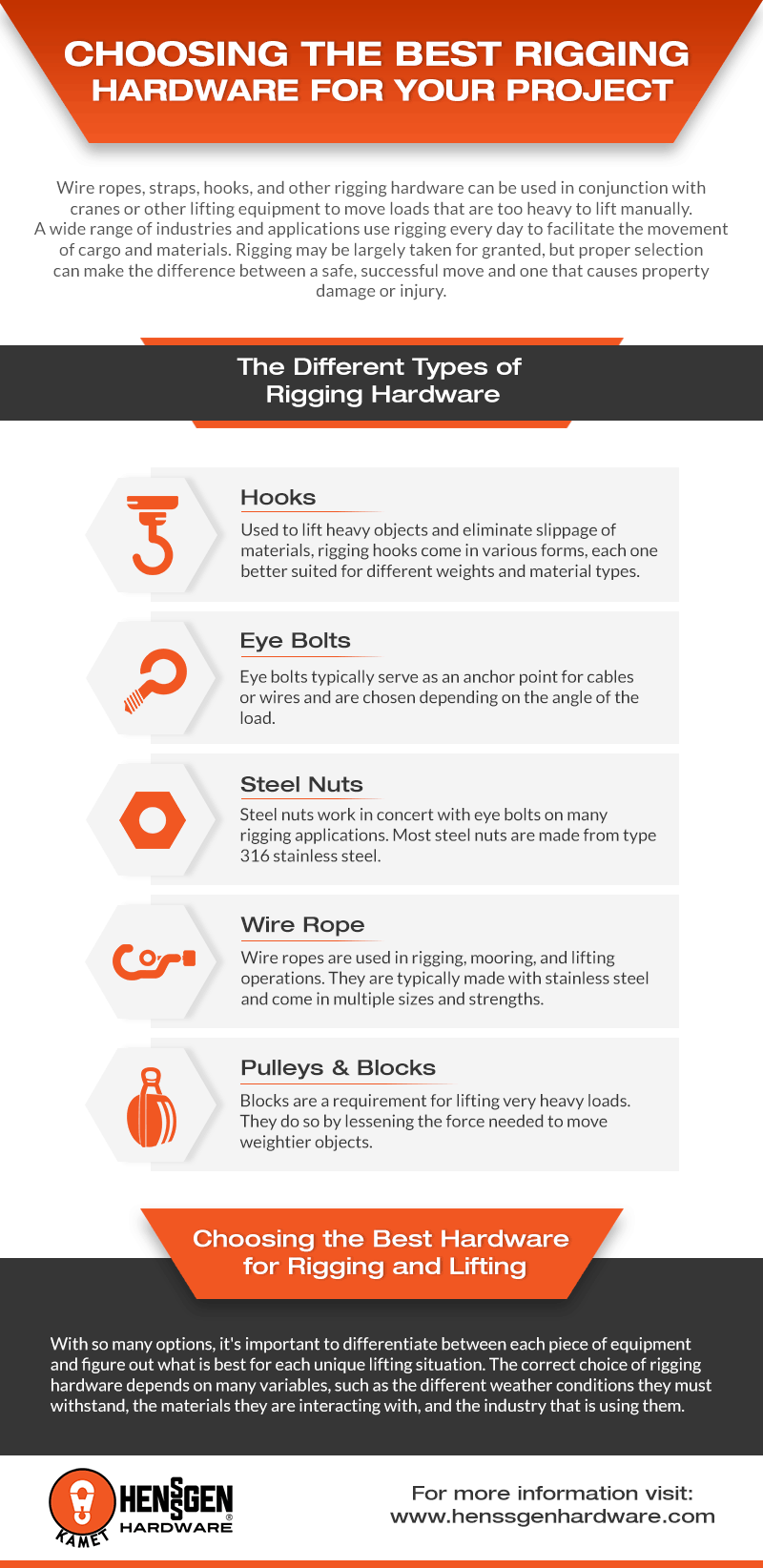

Wire ropes, straps, hooks, and other rigging hardware can be used in conjunction with cranes or other lifting equipment to move loads that are too heavy to lift manually. A wide range of industries and applications use rigging every day to facilitate the movement of cargo and materials. Rigging may be largely taken for granted, but proper selection can make the difference between a safe, successful move and one that causes property damage or injury.

Strict safety guidelines must be followed to avoid accidents. There are several steps users should take to make sure everything is used correctly. These include:

- Familiarizing all users and stakeholders with information contained within equipment user manuals.

- Proper training on all rigging and lifting equipment for all operators.

- Conducting regular preventative maintenance on all rigging and lifting equipment.

- Adhering to all safety and operational standards set forth by OSHA and other regulating bodies.

The Different Types of Rigging Hardware

Rigging selection can be a complex process, with many different forms of hardware made specifically for certain weights, situations, and environments. Common forms of rigging hardware include:

Hooks

Used to lift heavy objects and eliminate slippage of materials, rigging hooks come in various forms, each one better suited for different weights and material types. The most common styles include:

- Hoist hooks

- Lifting hooks

- Rigging hooks

- Sling hooks

Eye Bolts

Eye bolts typically serve as an anchor point for cables or wires and are chosen depending on the angle of the load. Eye bolt types include:

- Shoulder eye bolts

- Straight eye bolts

- Screw eye bolts

- U-bolts

- Lag eye screws

Steel Nuts

Steel nuts work in concert with eye bolts on many rigging applications. Most steel nuts are made from type 316 stainless steel. Nut types include:

- Hex nuts

- Ball ends

- Dome nuts

- Wing nuts

- Lifting eye nuts

Wire Ropes

Wire ropes are used in rigging, mooring, and lifting operations. They are typically made with stainless steel and come in multiple sizes and strengths. Wire ropes can be used in conjunction with clips, thimbles, and sleeves.

Pulleys & Blocks

Blocks are a requirement for lifting very heavy loads. They do so by lessening the force needed to move weightier objects. The most common type of block is the snatch block, but swivel blocks and square blocks are also viable options for specific applications. Blocks are easy to deploy, available in multiple sizes, and can accommodate up to 30 tons in weight. Pulleys, available in single and double varieties, tend to be combined with rigging ropes in order to hook onto objects securely. Pulley selection is dependent on rope, frame, and sheave size.

Choosing the Best Hardware for Rigging and Lifting

With so many options, it’s important to differentiate between each piece of equipment and figure out what is best for each unique lifting situation. The correct choice of rigging hardware depends on many variables, such as the different weather conditions they must withstand, the materials they are interacting with, and the industry that is using them.

Rigging is a versatile discipline. Divers use rigging hardware such as bolt snaps and D-rings to attach valuable items to fins, masks, regulators, ventilators, and tanks. Snap hooks, anchor chains, and trailer safety chains do a similar job as sailboat rigging hardware. Different harnesses may be used as saddle rigging hardware for horses, depending on the work load (breast collar harnesses for light work, breast strap harnesses for more strenuous activity). Rigging hardware is also useful for other recreational activities. Links, snaps, eye bolts, and D-rings are all useful ways to stay safe while rock climbing or water skiing.

Rigging hardware is an invaluable source of safety in many industrial, commercial, and recreational applications. Henssgen Hardware offers a wide range of solutions for your rigging needs. If you have any questions or want to request a quote, please contact us here.

0 Comments