There have been times that I’ve seen bronze and brass items being marketed in the same categories but they are quite different not only in their make up but also in appearance. Here is some information that will help guide you in determining which would be best for your project.

First, bronze dates back to 3500 BC with the Sumerians, also leading to the Bronze Age. Through its discovery, people were able to create more detailed metal sculptures and building materials (decorative tiles), a larger variety of tools, weapons, and armor. Bronze was a much stronger and more durable alternative to stone and copper.

Brass was introduced around 500 BC. Brass is made from an alloy of Copper and Zinc. Since Zinc is rarely if ever found in its natural state, early on people discovered melting copper and calamine (a zinc ore) yielded a golden colored tarnish resistant metal. It was quite useful due to a high melting point and it’s malleability.

Below is a Comparison Chart that will clearly highlight the similarities and differences between the two metals:

Brass vs Bronze

| Brass | Bronze | |

|---|---|---|

| Composition: | Brass is an alloy of copper and zinc. | Bronze is a metal alloy consisting primarily of copper, usually with tin as the main additive, but sometimes with other elements such as phosphorus, manganese, aluminum, or silicon. |

| Properties: | Higher malleability than zinc or copper. Low melting point (900 c); flows when melted. Combinations of iron, aluminum, silicon & manganese make brass corrosion resistant. Susceptible to stress cracking when exposed to ammonia. Not as hard as steel. | Hard and brittle. Melts at 950 centigrade but depends on amount of tin present. Bronze resists corrosion (especially seawater corrosion) and metal fatigue more than steel and is also a better conductor of heat and electricity than most steels. |

| Color: | Muted yellow, somewhat similar to gold, but duller. | Reddish brown. |

| Uses: | Decorative; Low-friction applications (locks, gears, doorknobs, ammunition, valves); Plumbing / electronics; Musical instruments for acoustic properties; Zippers & uses where it’s important to negate spark (fittings & tools around explosive gas), boat and marine hardware | Used in boat and ship fittings, propellers and submerged bearings because of resistance to salt water corrosion. Widely used for cast bronze sculpture; Bearings, clips, electrical connectors and springs; For top-quality bells and cymbals. |

| History: | Brass was first known to exist in about 500 BC. | Bronze dates to about 3500 BC. |

Brass Hardware

Brass’s malleability and innate corrosion resistance make the metal ideal for a wide variety of hardware purposes. Its muted gold color is highly recognizable and can perform as both a decorative and functional element. While it can be confused with bronze, its unique properties and applications make brass a category unto itself.

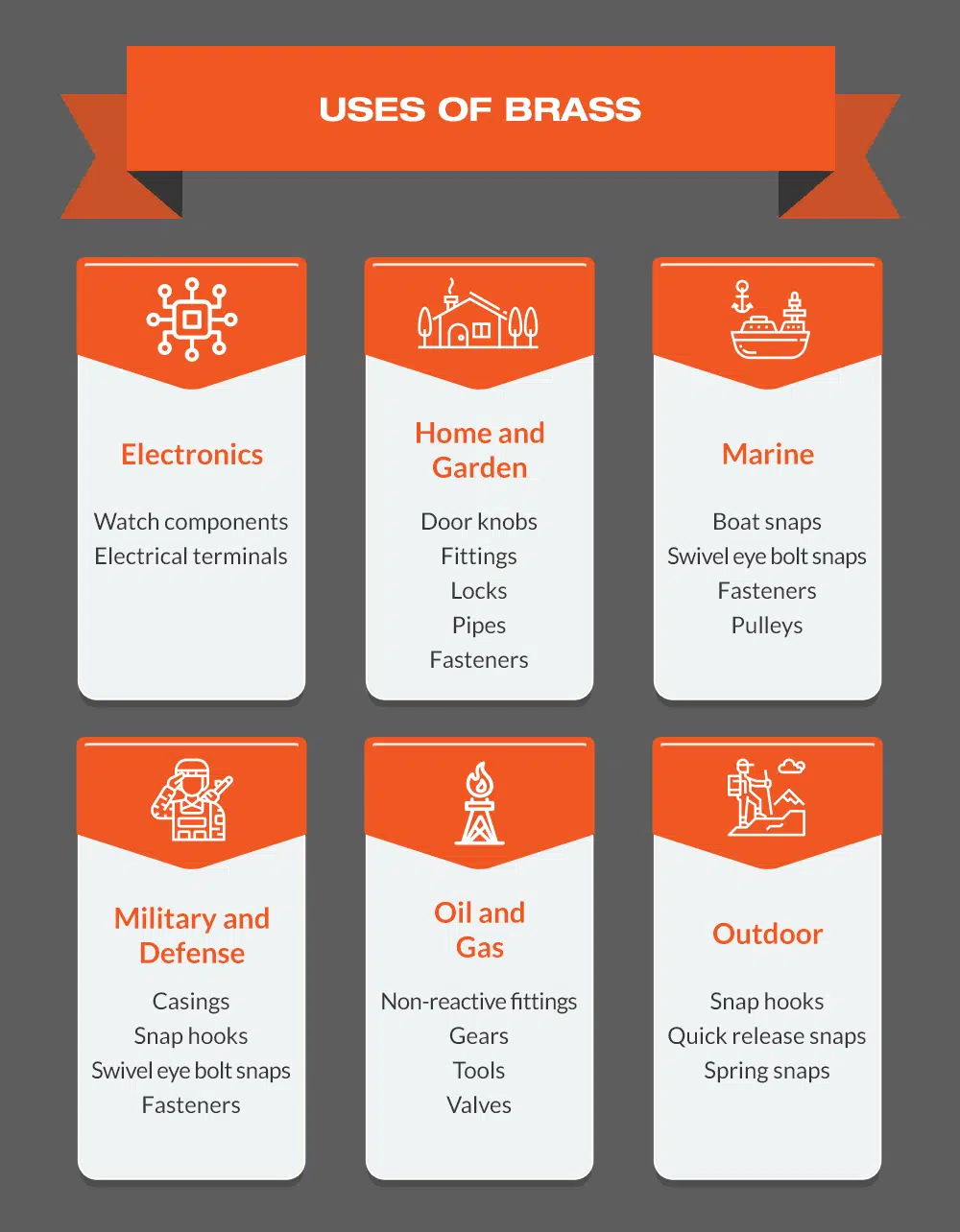

Uses of Brass—Brass Hardware Applications

Brass is used across multiple industries to create corrosion- and spark-resistant fixtures, fasteners, and equipment components. Brass goods can last for many years, whether indoors and outdoors.

Popular hardware applications for brass include:

- Electronics (watch components, electrical terminals)

- Home and garden (door knobs, fittings, locks, pipes, fasteners)

- Marine (boat snaps, swivel eye bolt snaps, fasteners, pulleys)

- Military and defense (casings, snap hooks, swivel eye bolt snaps, fasteners)

- Oil and gas (non-reactive fittings, gears, tools, and valves)

- Outdoor (snap hooks, quick release snaps, spring snaps)

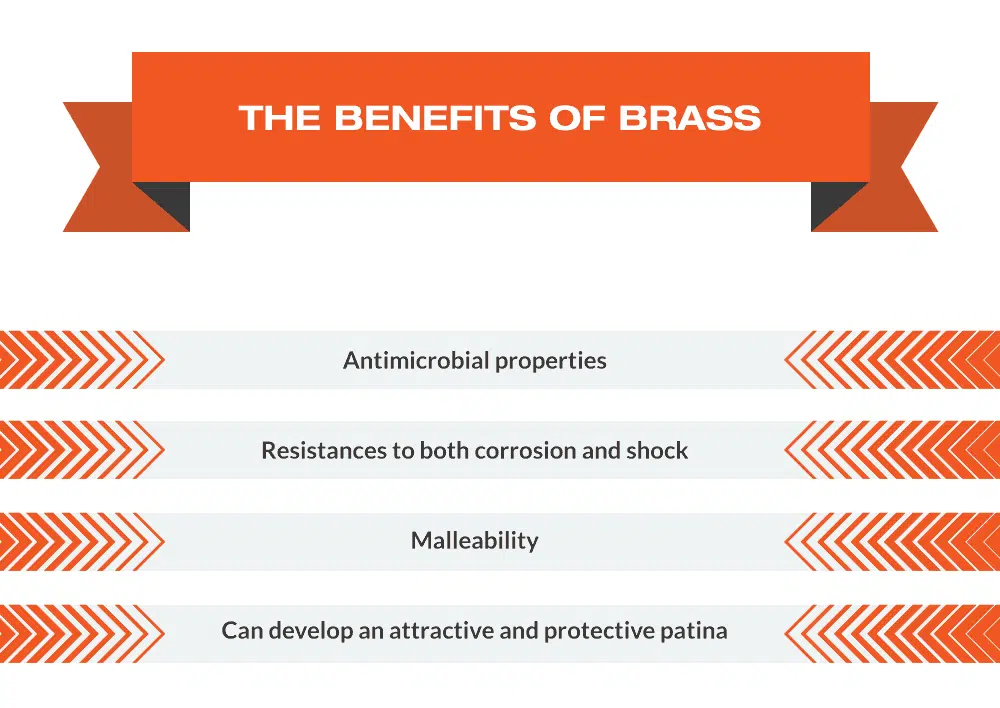

The Benefits of Brass

Brass possesses several unique features that make it a solid choice for fabrication and machining.

Some of these benefits include:

- Antimicrobial properties

- Resistances to both corrosion and shock

- Malleability

- Can develop an attractive and protective patina

Aside from these advantages, one of brass’s strongest benefits is its decorative appearance. The shine matches well with most woods and warmer colors.

Types of Solid Brass Hardware

Henssgen Hardware offers a wide variety of brass components and fasteners. Brass hardware is reliable, sturdy, and decorative, so each fastener can be used in visible or customer-facing environments. We always construct our fasteners with solid brass instead of offering brass-plated products that remain susceptible to corrosion.

0 Comments